Polystyrene

Polystyrene (pronounced /ˌpɒliˈstaɪriːn/) (IUPAC Poly(1-phenylethane-1,2-diyl)), abbreviated following ISO Standard PS, is an aromatic polymer made from the aromatic monomer styrene, a liquid hydrocarbon that is commercially manufactured from petroleum by the chemical industry. Polystyrene is one of the most widely used kinds of plastic.

Polystyrene is a thermoplastic substance, which is in solid (glassy) state at room temperature, but flows if heated above its glass transition temperature (for molding or extrusion), and becomes solid again when it cools off. Pure solid polystyrene is a colorless, hard plastic with limited flexibility. It can be cast into molds with fine detail. Polystyrene can be transparent or can be made to take on various colors.

Solid polystyrene is used, for example, in disposable cutlery, plastic models, CD and DVD cases, and smoke detector housings. Products made from foamed polystyrene are nearly ubiquitous, for example packing materials, insulation, and foam drink cups.

Polystyrene can be recycled, and has the number "6" as its recycling symbol. Polystyrene takes a very long time to biodegrade[1], and is often abundant as a form of pollution in the outdoor environment, particularly along shores and waterways.

Contents |

History

Polystyrene was discovered in 1839 by Eduard Simon,[2] an apothecary in Berlin. From storax, the resin of the Turkish sweetgum tree (Liquidambar orientalis), he distilled an oily substance, a monomer which he named styrol. Several days later, Simon found that the styrol had thickened, presumably from oxidation, into a jelly he dubbed styrol oxide ("Styroloxyd"). By 1845 English chemist John Blyth and German chemist August Wilhelm von Hofmann showed that the same transformation of styrol took place in the absence of oxygen. They called their substance metastyrol. Analysis later showed that it was chemically identical to Styroloxyd. In 1866 Marcelin Berthelot correctly identified the formation of metastyrol from styrol as a polymerization process. About 80 years went by before it was realized that heating of styrol starts a chain reaction which produces macromolecules, following the thesis of German organic chemist Hermann Staudinger (1881–1965). This eventually led to the substance receiving its present name, polystyrene.

The company I. G. Farben began manufacturing polystyrene in Ludwigshafen, Germany, about 1931, hoping it would be a suitable replacement for die-cast zinc in many applications. Success was achieved when they developed a reactor vessel that extruded polystyrene through a heated tube and cutter, producing polystyrene in pellet form.

Before 1949, the chemical engineer Fritz Stastny, 1908–1985, developed pre-expanded PS beads by incorporating aliphatic hydrocarbons, such as pentane. These beads are the raw material for moulding parts or extruding sheets. BASF and Stastny applied for a patent which was issued in 1949. The moulding process was demonstrated at the Kunststoff Messe 1952 in Düsseldorf. Products were named Styropor.

In 1959, the Koppers Company in Pittsburgh, Pennsylvania, developed expanded polystyrene (EPS) foam.

Structure and properties

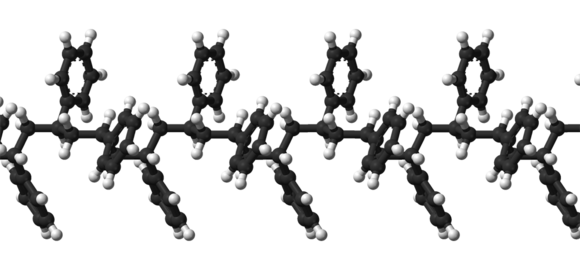

The chemical makeup of polystyrene is a long chain hydrocarbon with every other carbon connected to a phenyl group (the name given to the aromatic ring benzene, when bonded to complex carbon substituents). Polystyrene's chemical formula is (C8H8)n; it contains the chemical elements carbon and hydrogen. Because it is an aromatic hydrocarbon, it burns with an orange-yellow flame, giving off soot, as opposed to non-aromatic hydrocarbon polymers such as polyethylene, which burn with a light yellow flame (often with a blue tinge) and no soot. Complete oxidation of polystyrene produces only carbon dioxide and water vapor.

This addition polymer of styrene results when vinyl benzene (styrene) monomers (which contain double bonds between carbon atoms) attach to form a polystyrene chain (with each carbon attached with a single bond to two other carbons and a phenyl group).

Let us consider polystyrene's properties based on its structure shown above. Polystyrene is chemically unreactive (this is why it is used to create products such as containers for chemicals, solvents and foods). This stability is the result of the transformation of carbon-carbon double bonds into less reactive single bonds. Structurally, the unsaturated alkene monomers have been transformed into more saturated structures with carbon alkane backbones. A molecule is considered saturated when its carbons are bonded to the maximum number of hydrogen atoms possible. The strong bonds within the molecule make styrene very stable.

Polystyrene is generally flexible and can come in the form of moldable solids or viscous liquids. The force of attraction in polystyrene is mainly due to short range van der Waals attractions between chains. Since the molecules and long hydrocarbon chains that consist of thousand of atoms, the total attractive force between the molecules is large. However, when the polymer is heated (or, equivalently, deformed at a rapid rate, due to a combination of viscoelastic and thermal insulation properties), the chains are able to take on a higher degree of conformation and slide past each other. This intermolecular weakness (versus the high intramolecular strength due to the hydrocarbon backbone) allows the polystyrene chains to slide along each other, rendering the bulk system flexible and stretchable. The ability of the system to be readily deformed above its glass transition temperature allows polystyrene (and thermoplastic polymers in general) to be readily softened and molded with the addition of heat.

A 3-D model would show that each of the chiral backbone carbons lies at the center of a tetrahedron, with its 4 bonds pointing toward the vertices. Say the -C-C- bonds are rotated so that the backbone chain lies entirely in the plane of the diagram. From this flat schematic, it is not evident which of the phenyl (benzene) groups are angled toward us from the plane of the diagram, and which ones are angled away. The isomer where all of them are on the same side is called isotactic polystyrene, which is not produced commercially.

|

|

|

Ordinary atactic polystyrene has these large phenyl groups randomly distributed on both sides of the chain. This random positioning prevents the chains from ever aligning with sufficient regularity to achieve any crystallinity, so the plastic has a very low melting point, Tm<<TRT. But metallocene-catalyzed polymerization can produce an ordered syndiotactic polystyrene with the phenyl groups on alternating sides. This form is highly crystalline with a Tm of 270 °C (518 °F).

Extruded polystyrene is about as strong as unalloyed aluminium, but much more flexible and much lighter (1.05 g/cm3 vs. 2.70 g/cm3 for aluminium).

Forms produced

| Properties | |

|---|---|

| Density | 1.05 g/cm3 |

| Density of EPS | 16–640 kg/m3[4] |

| Dielectric constant | 2.4–2.7 |

| Electrical conductivity (s) | 10−16 S/m |

| Thermal conductivity (k) | 0.08 W/(m·K) |

| Young's modulus (E) | 3000–3600 MPa |

| Tensile strength (st) | 46–60 MPa |

| Elongation at break | 3–4% |

| Notch test | 2–5 kJ/m2 |

| Glass temperature | 95 °C |

| Melting point[5] | 240 °C |

| Vicat B | 90 °C[6] |

| Linear expansion coefficient (a) | 8×10−5 /K |

| Specific heat (c) | 1.3 kJ/(kg·K) |

| Water absorption (ASTM) | 0.03–0.1 |

| Decomposition | X years, still decaying |

Polystyrene is commonly injection molded or extruded, while expanded polystyrene is either extruded or molded in a special process. Polystyrene copolymers are also produced; these contain one or more other monomers in addition to styrene. In recent years the expanded polystyrene composites with cellulose[7][8] and starch[9] have also been produced.

Extruded closed-cell polystyrene foam is sold under the trademark Styrofoam by Dow Chemical. This term is often used informally for other foamed polystyrene products.

Polystyrene is used in some polymer-bonded explosives:

| Name | Explosive ingredients | Binder ingredients |

|---|---|---|

| PBX-9205 | RDX 92% | Polystyrene 6%; DOP 2% |

| PBX-9007 | RDX 90% | Polystyrene 9.1%; DOP 0.5%; resin 0.4% |

It is also a component of napalm[10] and a component of most designs of hydrogen bombs.

Sheet or molded polystyrene

Polystyrene (PS) is economical, and is used for producing plastic model assembly kits, plastic cutlery, CD "jewel" cases, smoke detector housings, license plate frames, and many other objects where a fairly rigid, economical plastic is desired. Production methods include thermoforming and injection molding.

Polystyrene Petri dishes and other laboratory containers such as test tubes and microplates play an important role in biomedical research and science. For these uses, articles are almost always made by injection molding, and often sterilized post-molding, either by irradiation or treatment with ethylene oxide. Post-mold surface modification, usually with oxygen-rich plasmas, is often done to introduce polar groups. Much of modern biomedical research relies on the use of such products; they therefore play a critical role in pharmaceutical research.[11]

Foams

Polystyrene foams are good thermal insulators and are therefore often used as building insulation materials, such as in structural insulated panel building systems. They are also used for non-weight-bearing architectural structures (such as ornamental pillars). PS foams exhibit also good damping properties, therefore it is used widely in packaging.

Expanded polystyrene

Expanded polystyrene (EPS) is a rigid and tough, closed-cell foam. It is usually white and made of pre-expanded polystyrene beads. Familiar uses include molded sheets for building insulation and packing material ("peanuts") for cushioning fragile items inside boxes. Sheets are commonly packaged as rigid panels (size 4 by 8 or 2 by 8 feet in the United States), which are also known as "bead-board". Thermal resistivity is usually about 28 m·K/W (or R-4 per inch in American customary units). Some EPS boards have a flame spread of less than 25 and a smoke-developed index of less than 450, which means they can be used without a fire barrier (but require a 15 minute thermal barrier) according to US building codes. A growing use of EPS in construction is Insulating concrete forms. The density range is about 16–640 kg/m3.[4] The most common processing method is thermal cutting with hot wires.[12]

Extruded polystyrene foam

Extruded polystyrene foam (XPS) consists of closed cells, offers improved surface roughness as higher stiffness and reduced thermal conductivity. The density range is about 28 – 45 kg/m3.

Extruded polystyrene material is also used in crafts and model building, particularly architectural models. Because of the extrusion manufacturing process, XPS does not require facers to maintain its thermal or physical property performance. Thus, it makes a more uniform substitute for corrugated cardboard. Thermal resistivity is usually about 35 m·K/W (or R-5 per inch in American customary units).

Styrofoam is a trademarked name for XPS, however it is often also used in the United States as a generic name for all polystyrene foams.

Copolymers

Pure polystyrene is brittle, but hard enough that a fairly high-performance product can be made by giving it some of the properties of a stretchier material, such as polybutadiene rubber. The two such materials can never normally be mixed because of the amplified effect of intermolecular forces on polymer insolubility (see plastic recycling), but if polybutadiene is added during polymerization it can become chemically bonded to the polystyrene, forming a graft copolymer which helps to incorporate normal polybutadiene into the final mix, resulting in high-impact polystyrene or HIPS, often called "high-impact plastic" in advertisements. One commercial name for HIPS is Bextrene. Common applications of HIPS include toys and product casings. HIPS is usually injection molded in production. Autoclaving polystyrene can compress and harden the material.

Several other copolymers are also used with styrene. Acrylonitrile butadiene styrene or ABS plastic is similar to HIPS: a copolymer of acrylonitrile and styrene, toughened with polybutadiene. Most electronics cases are made of this form of polystyrene, as are many sewer pipes. SAN is a copolymer of styrene with acrylonitrile, and SMA one with maleic anhydride. Styrene can be copolymerized with other monomers; for example, divinylbenzene for cross-linking the polystyrene chains.

Oriented polystyrene

Oriented polystyrene (OPS) is produced by stretching extruded PS film, improving stiffness.

Disposal and environmental issues

Polystyrene is not easily recycled because of its light weight (especially if foamed) and its low scrap value. It is generally not accepted in kerbside (curbside) collection recycling programs. In Germany, however, polystyrene is collected, as a consequence of the packaging law (Verpackungsverordnung) that requires manufacturers to take responsibility for recycling or disposing of any packaging material they sell.

Environmental impact

Discarded polystyrene does not biodegrade for five hundred years and is resistant to photolysis.[13] Because of this, very little of the waste discarded in today's modern, highly engineered landfills biodegrades. Because degradation of materials creates potentially harmful liquid and gaseous by-products that could contaminate groundwater and air, today's landfills are designed to minimize contact with air and water required for degradation, thereby practically eliminating the degradation of waste.[14]

Polystyrene foam is a major component of plastic debris in the ocean, where it becomes toxic to marine life. Foamed polystyrene blows in the wind and floats on water, and is abundant in the outdoor environment. Weathering by wind, sun, rain, and wave action degrade polystyrene to known and suspected carcinogens, including styrene monomer (SM), styrene dimer (SD) and styrene trimer (ST). [15] [16][17] However, styrene is an organic, naturally occurring substance in our environment and to date, no regulatory body anywhere in the world has classified styrene as a known human carcinogen, although several refer to it in various contexts as a possible or potential human carcinogen.[18] Furthermore, styrene is quickly broken down in the air, evaporates quickly in shallow soil and water, and what remains in soil and water can be further broken down by bacteria and microorganisms.[19][20]

Polystyrene foams are produced using blowing agents that form bubbles and expand the foam. In expanded polystyrene, these are usually hydrocarbons such as pentane, which may pose a flammability hazard in manufacturing or storage of newly manufactured material, but have relatively mild environmental impact. However, extruded polystyrene is usually made with hydrochlorofluorocarbons (HCFC) blowing agents which have effects on ozone depletion and on global warming. Their ozone depletion potential is greatly reduced relative to chlorofluorocarbon (CFC) which were formerly used, but their global warming potential can be on the order of 1000 or more, meaning it has 1000 times greater effect on global warming than does carbon dioxide.[21]

That being said, global warming regulations should have minimal direct impact on the PS industry. There are few greenhouse gas emissions generated by the PS industry in comparison to other industries such as oil refineries and automobiles.[22]

Regardless, on September 21, 2007, approximately 200 countries agreed to accelerate the elimination of hydrochlorofluorocarbons entirely by 2020 in a United Nations-sponsored Montreal summit. Developing nations were given until 2030.[23] Ultimately, hydrofluorocarbons (HFCs) will replace HCFCs with essentially no ozone destruction.

While there is less concern about the health effects of EPS itself, the brominated flame retardants used in most EPS foam (decaBDE or hexabromocyclododecane are the most commonly used) could possibly create health and environmental risks that are generating some concern with the EPA.[24]

Since the early 1990s, starch-based foam packing peanuts have been used as a replacement for PS packing peanuts. Foamed poly-lactic acid (PLA), marketed as Biofoam[25], has also been developed.

In 2007, Eben Bayer, a student at Rensselaer Polytechnic Institute, invented[26] an environmentally-friendly replacement for polystyrene packaging using the mineral perlite bonded with lignin-containing agricultural waste, degraded by fungi, which he calls Ecocradle.[27]

Recycling

Currently, the majority of polystyrene products are not recycled. Expanded polystyrene scrap can be easily added to products such as EPS insulation sheets and other EPS materials for construction applications. Commonly, manufacturers cannot obtain sufficient scrap because of the aforementioned collection issues. When it is not used to make more EPS, foam scrap can be turned into clothes hangers, park benches, flower pots, toys, rulers, stapler bodies, seedling containers, picture frames, and architectural molding from recycled PS.[28]

Recycled EPS is also used in many metal casting operations. Rastra is made from EPS that is combined with cement to be used as an insulating amendment in the making of concrete foundations. American manufacturers have produced insulated concrete forms made with approximately 80% recycled EPS since 1993. However, polystyrene recycling is not a closed loop, producing more polystyrene; polystyrene cups and other packaging materials are instead usually used as fillers in other plastics, or in other items that cannot themselves be recycled and are thrown away.

Incineration

If polystyrene is properly incinerated at high temperatures, the only chemicals generated are water, carbon dioxide, some volatile compounds, and carbon soot.[29] According to the American Chemistry Council, when polystyrene is incinerated in modern facilities, the final volume is 1% of the starting volume; most of the polystyrene is converted into carbon dioxide, water vapor, and heat. Because of the amount of heat released, it is sometimes used as a power source for steam or electricity generation.[30]

When polystyrene was burned at temperatures of 800-900 °C (the typical range of a modern incinerator), the products of combustion consisted of "a complex mixture of polycyclic aromatic hydrocarbons (PAHs) from alkyl benzenes to benzo[ghi]perylene. Over 90 different compounds were identified in combustion effluents from polystyrene."[31]

When burned without enough oxygen or at lower temperatures (as in a campfire or a household fireplace), polystyrene can produce polycyclic aromatic hydrocarbons, carbon black, and carbon monoxide, as well as styrene monomers.[29][32]

Burial

Foam cups and other polystyrene products can be safely buried in landfills, since it is as stable as concrete or brick. No plastic film is required to protect the air and underground water.

Reducing

Some effort is being made to find alternatives to polystyrene foam, especially in restaurant settings. Restricting the use of foamed polystyrene takeout food packaging is a priority of many solid waste environmental organizations. However, the Plastics Foodservice Packaging Group counters that in US, less than 1% by weight of solid waste disposed is polystyrene. A campaign to achieve the first ban of polystyrene foam from the food & beverage industry in Canada was launched in Toronto as of January 2007, by local non-profit organization NaturoPack.[33]. Portland, Ore., and San Francisco are among about one hundred cities in the United States that currently have some sort of ban on polystyrene foam in restaurants. For instance, in 2007 restaurants in Oakland, California were required to switch to disposable food containers that will biodegrade if added to food compost.[34]

Although polystyrene can be recycled at recycling facilities, most polystyrene is not recycled. The EPA (United States Environmental Protection Agency) estimates that 25 billion polystyrene cups are tossed every year. Since polystyrene degrades very slowly- more than 500 years for a single cup- the EPA considers this a serious environmental problem. Several green leaders, from the Dutch Ministry of the Environment to Starbucks' Green Team, advise that individuals reduce their environmental impact by using reusable coffee cups.[35]

Finishing

In the United States, environmental protection regulations prohibit the use of solvents on polystyrene (which would dissolve the polystyrene and de-foam most foams anyway).

Some acceptable finishing materials are

- Water-based paint (artists have created paintings on polystyrene with gouache)

- Mortar or acrylic/cement render, often used in the building industry as a weather-hard overcoat that hides the foam completely after finishing the objects.

- Cotton wool or other fabrics used in conjunction with a stapling implement.

Health and fire hazards

There has been concern about the trace presence of polystyrene's production chemicals in the final plastic product, most of which are toxic if not removed. For instance benzene, which is used to produce ethylbenzene for styrene, is a known carcinogen. As well, unpolymerized styrene may pose health risks.

However,

Based on scientific tests over five decades, government safety agencies have determined that polystyrene is safe for use in foodservice products. For example, polystyrene meets the stringent standards of the U.S. Food and Drug Administration and the European Commission/European Food Safety Authority for use in packaging to store and serve food. The Hong Kong Food and Environmental Hygiene Department recently reviewed the safety of serving various foods in polystyrene foodservice products and reached the same conclusion as the U.S. FDA.[36]

and from 1999 to 2002, a comprehensive review of the potential health risks associated with exposure to styrene was conducted by a 12 member international expert panel selected by the Harvard Center for Risk Assessment. The scientists had expertise in toxicology, epidemiology, medicine, risk analysis, pharmacokinetics, and exposure assessment.

The Harvard study reported that styrene is naturally present in foods such as strawberries, beef, and spices, and is naturally produced in the processing of foods such as wine and cheese. The study also reviewed all the published data on the quantity of styrene contributing to the diet due to migration of food packaging and disposable food contact articles, and concluded there is no cause for concern for the general public from exposure to styrene from foods or styrenic materials used in food-contact applications, such as polystyrene packaging and food service containers.[37]

The LD50 of styrene is 3 mmol/kg as determined by the Registry of Cytotoxicity Data (ZEBET) 7.1, National Institute of Health, Berlin, Germany.

There are, of course, studies concerning polystyrene containers used for food packaging which find that styrene oligomers migrate into the food.[38]. For instance, one Japanese study conducted on wild-type and AhR-null mice found that the styrene trimer, which the authors detected in cooked polystyrene container-packed instant foods, may increase thyroid hormone levels.[39]

Polystyrene is classified according to DIN4102 as a "B3" product, meaning highly flammable or "easily ignited." Consequently, although it is an efficient insulator at low temperatures, its use is prohibited in any exposed installations in building construction if the material is not flame retardant, e.g., with hexabromocyclododecane. It must be concealed behind drywall, sheet metal or concrete. Foamed polystyrene plastic materials have been accidentally ignited and caused huge fires and losses, for example at the Düsseldorf International Airport, the Channel tunnel (where polystyrene was inside a railcar that caught fire), and the Browns Ferry Nuclear Power Plant (where fire breached a fire retardant and reached the foamed plastic underneath, inside a firestop that had not been tested and certified in accordance with the final installation).

In addition to fire hazard, polystyrene can be dissolved by substances that contain acetone (such as most aerosol paint sprays), and by cyanoacrylate glues.

See also

- Bioplastic

- Insulating concrete forms

- Geofoam

- Structural insulated panel

- Styrofoam

References

- ↑ Bandyopadhyay, Abhijit; Chandra Basak, G. (2007). "Studies on photocatalytic degradation of polystyrene". Materials Science and Technology 23 (3): 307–317. doi:10.1179/174328407X158640.

- ↑ The history of plastics

- ↑ G. Natta, P. Corradini, I.W. Bassi (1960). "Crystal structure of isotactic polystyrene". Il Nuovo Cimento 15: 68–82. doi:10.1007/BF02731861.

- ↑ 4.0 4.1 K. Goodier (June 22, 1961). "Making and using an expanded plastic". New Scientist 240: 706. http://books.google.com/?id=d_XOKdeyXrYC&pg=PA706.

- ↑ International Labour Organisation chemical safety card for polystyrene

- ↑ A.K. van der Vegt & L.E. Govaert, Polymeren, van keten tot kunstof, ISBN 90-407-2388-5

- ↑ Doroudiani S, Kortschot MT (2004). "Expanded Wood Fiber Polystyrene Composites: Processing-Structure-Mechanical Properties Relationships". Journal of Thermoplastic Composite Materials 17: 13–30. doi:10.1177/0892705704035405.

- ↑ Doroudiani, Saeed; Chaffey, Charles E.; Kortschot, Mark T. (2002). "Sorption and diffusion of carbon dioxide in wood-fiber/polystyrene composites". Journal of Polymer Science Part B: Polymer Physics 40: 723. doi:10.1002/polb.10129.

- ↑ Mihai, M.; Huneault, M. A.; Favis, B. D. (2007). "Foaming of Polystyrene/ Thermoplastic Starch Blends". Journal of Cellular Plastics 43: 215. doi:10.1177/0021955X07076532.

- ↑ Napalm

- ↑ Jed Norton. "Blue Foam, Pink Foam and Foam Board". Antenociti's Workshop. http://www.barrule.com/workshop/images/info/foams/index.htm. Retrieved 2008-01-29.

- ↑ Expandable Polystyrene, Insight database from Ceresana Research

- ↑ Bandyopadhyay, Abhijit; Chandra Basak, G. (2007). "Studies on photocatalytic degradation of polystyrene". Materials Science and Technology 23 (3): 307–317. doi:10.1179/174328407X158640.

- ↑ William Rathje and Cullen Murphy (1989). Rubbish! The Archeology of Garbage.

- ↑ http://www.sciencedaily.com/releases/2009/08/090819234651.htm

- ↑ Barry, Carolyn. "Plastic Breaks Down In Ocean, After All- And Fast." National Geographic 20 Aug. 2009:

- ↑ Scientists uncover new ocean threat from plastics, The Independent, 20 August 2009.

- ↑ International Agency for Research on Cancer (IARC) "Styrene is probably carcinogenic to humans. Group 2A", "IARC Monographs, Classifications", 1994

- ↑ Styrene Fact Sheet

- ↑ Denis H. James William M. Castor (2005). "Styrene". Ullmann’s Encyclopedia of Industrial Chemistry. Wiley-VCH.

- ↑ IPCC Third Assessment Report, Climate Change 2001: Working Group I: The Scientific Basis. Section 6.12.2 Direct GWPs.

- ↑ Polystyrene (PS) Frequently Asked Questions, American Chemistry Council

- ↑ HCFC Phaseout Schedule, US EPA

- ↑ EPA information on HBCD

- ↑ BioFoam® Synbra Group

- ↑ Shin, L. (2009). Using Fungi to Replace Styrofoam. NY Times.

- ↑ Evocative Designs LLC, Ecocradle

- ↑ Polystyrene recycling. Polystyrene packaging council. Retrieved on 2009-03-06.

- ↑ 29.0 29.1 Polystyrene Foam Burning Danger

- ↑ "Ease of Disposal". http://www.americanchemistry.com/s_plastics/sec_pfpg.asp?CID=1434&did=5226. Retrieved 2009-06-25.

- ↑ Hawley-Fedder, R.A.; Parsons, M.L. and Karasek, F.W. (1984). "Products obtained during combustion of polymers under simulated incinerator conditions II. Polystyrene". Products Obtained During Combustion of Polymers Under Simulated Incinerator Conditions, II Polystyrene 315: 201. doi:10.1016/S0021-9673(01)90737-X. http://www.ejnet.org/plastics/polystyrene/disposal.html.

- ↑ Burning Polystyrene Foam

- ↑ Naturopack Campaign Page

- ↑ Hadish, Cindy. "Food for thought: 100 U.S. cities enact bans." Gazette, The (Cedar Rapids, IA) 2 Apr. 2008.

- ↑ Dineen, Shauna (Nov. - Dec. 2005). "The Throwaway Generation: 25 Billion Styrofoam Cups a Year". E-The Environmental Magazine. http://www.emagazine.com/view/?2933.

- ↑ Q & A on the Safety of Polystyrene Foodservice Products

- ↑ Cohen, Joshua T.; Carlson, Gary; Charnley, Gail; Coggon, David; Delzell, Elizabeth; Graham, John D.; Greim, Helmut; Krewski, Daniel et al. (2002). "A comprehensive evaluation of the potential health risks associated with occupational and environmental exposure to styrene". Journal of Toxicology and Environmental Health Part B: Critical Reviews 5: 1. doi:10.1080/10937400252972162.

- ↑ Sakamato H, Matsuzawa A, Itoh R, Tohyama Y (2000). "Quantitative Analysis of Styrene Dimer and Trimers Migrated from Disposable Lunch Boxes". J Food Hyg Soc Japan 41: 200–205. doi:10.3358/shokueishi.41.200. http://sciencelinks.jp/j-east/article/200016/000020001600A0689499.php.

- ↑ Yanagiba, Yukie et al. (2008). "Styrene Trimer May Increase Thyroid Hormone Levels via Down-Regulation of the Aryl Hydrocarbon Receptor (AhR) Target Gene UDP-Glucuronosyltransferase" (free text). Environmental Health Perspectives 116 (6): 740–745. doi:10.1289/ehp.10724. PMID 18560529. PMC 2430229. http://www.ncbi.nlm.nih.gov/pmc/articles/PMC2430229/.

External links

- Polystyrene - The University of Southern Mississippi

- SPI resin identification code - Society of the Plastics Industry

- Bacteria Turns Styrofoam into Biodegradable Plastic - Scientific American, February 27, 2006

- Polystyrene (packaging) facts

Plastics Foodservice Packaging Group (PFPG) of the American Chemistry Council

|

||||||||||||||||||||

|

|||||